Researchers at Sandia National Laboratories study the burning process of alternative fuels using use complex computer models, petabytes of data and Tecplot 360

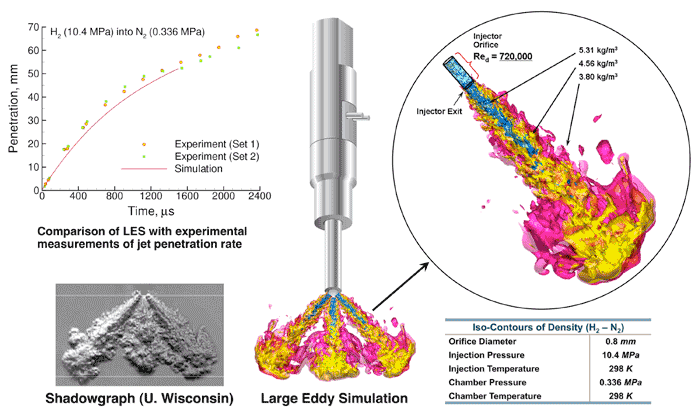

A close up view of the large eddy simulation.

(Full image shown below.)

Transportation by automobiles and trucks in the United States accounts for two-thirds of our oil use and one-fourth of our greenhouse gas emissions. Thus, the interdependent advancement of both fuel and engine technologies is a key component of the strategy to dramatically reduce both oil consumption and greenhouse gases. Today, it is more important than ever to find alternate fuel sources that can run our global economy as efficiently and effectively as oil. However, the problem is as complex as the molecules that make up the substance itself.

The Problem with Oil

First, there’s the concern about dwindling supplies at a time when world populations, industrialization and demand for fuel are skyrocketing. Debates about if or when the world will run out of oil have raged for years. But it’s fairly clear that reserves of quality, easily extractable, light crude oil are shrinking. In the coming years, more and more resources will be needed to recover oil in hard-to-reach places, squeeze a little more oil out of older fields and find ways of extracting it from substances like coal or shale. Layer on top of that global concerns about increasing air pollution, environmental damage caused by oil spills, as well as too much dependency on foreign oil and the case for developing viable alternate fuels for combustion engines becomes quite compelling.

Researchers Meeting the Challenge

Jacqueline Chen and Joseph Oefelein are two scientists working at the Livermore, Calif. Combustion Research Facility of Sandia National Laboratories to help the U.S. Department of Energy meet this great challenge. Both are leaders in computational combustion science and have developed high-fidelity simulation approaches well suited for taking advantage of high-performance computers operated by the Department of Energy’s Office of Science.

These researchers are using some of the world’s fastest supercomputers to study the burning processes associated with a variety of fuels. By understanding more thoroughly how each of these fuels works, engineers can design internal combustion engines that burn alternative fuels in a way that maximizes performance and minimizes emissions.

To quickly interpret their computationally intensive data, Oefelein and Chen rely on Tecplot 360, computational fluid dynamics (CFD) visualization and analysis software that combines engineering plotting and advanced data visualization into one tool.

Oefelein and Chen rely on Tecplot 360, computational fluid dynamics (CFD) visualization and analysis software that combines engineering plotting and advanced data visualization into one tool.

Understanding How the Engine Works with Alternative Fuels

With fossil fuels in widespread use since the mid-1850s, industry experts know exactly how the internal combustion engine functions with petroleum-based fuels like gasoline and diesel. But this kind of knowledge won’t transfer because different fuels respond quite differently to diverse temperatures and pressures and acquiring this new knowledge quickly requires some extremely complicated computational models.

“Moving from one type of fuel to the next, the molecular structure of the fuel changes a lot,” says Oefelein. “Understanding these different nuances requires very reliable computations and models.”

Oefelein and Chen are performing high-fidelity simulations to understand the complex thermo-chemical interactions encountered in internal combustion engines with carbon-neutral fuels such as biofuels, and alcohols like ethanol and dimethyl ether. One key goal of their research is to maximize the way alternative fuels are used by the next generation of internal combustion engines.

“You always want a clean burning, highly efficient system,” says Oefelein. “And you want it to be a stable system, meaning that there are no combustion instabilities or transient types of processes that will damage the engine.”

Large Eddy Simulation

To develop predictive models for designing clean and fuel-efficient engines, Oefelein and Chen are using two computational techniques. One, called “large eddy simulation,” is a numerical technique used to solve the partial differential equations governing turbulent fluid flow. With this approach, the energy containing eddying motions that are dependent upon the geometry of the combustor are resolved numerically and the dissipative small scale turbulence and combustion scales require closure models.

Direct Numerical Simulation

The other, known as “direct numerical simulation,” examines the whole range of spatial and temporal scales of turbulence and flames, and hence, is restricted to a limited dynamic range of scales. Often this approach is well suited for studying the micro-scales of turbulence chemistry interactions where turbulent mixing scales interact with the reactive flame and ignition scales. Hence, these two approaches complement one another with large-eddy simulation characterizing the large-scale entrainment and mixing processes and direct numerical simulation providing subgrid information regarding micromixing and reaction.

Both of these numerical techniques are incredibly computationally intensive, generating in many cases petabytes of data. To get a feel for just how much data this is, consider that one petabyte equals 1,000 terabytes – more than six times as much data as contained in the U.S. Library of Congress archive.

Large Eddy Simulation an automotive high-pressure fuel injector design for use in a hydrogen fuelled internal-combustion engine.

“Ten years ago, this research was at the terascale level in terms of computational speed, and now it’s at petascale,” says Chen. “In a few years, we’ll be at exascale. With the ever-increasing size of computers, we are able to simulate a wider dynamic range of scales.” Because of the daunting scaling of turbulence with Reynolds number, the ratio of inertial to viscous forces, for every 1,000 fold increase in computing power, researchers are only able to directly simulate a ten-fold increase in dynamic range of turbulence scales. Therefore, for the foreseeable future no one method will be able to resolve the entire range of scales relevant to practical combustors. Rather, a multi-scale approach is required where different methods are well suited to resolving different ranges of scales and models are used to bridge the gaps between the different ranges of scales.

Using Tecplot 360 to Accurately Interpret Massive Amounts of Data

Oefelein and Chen use Tecplot 360 to interpret and visualize the massive amounts of data required for their research. Often, they perform calculations on supercomputers located offsite. Using a dashboard, they send Tecplot images such as isocontour plots, 2D and 3D plots, and animations back to their facility, which helps them to quickly hone in on key statistics and identify critical trends. “The user interface and the drop-down menus are very intuitive,” says Chen.

A key benefit of Tecplot 360 is that it helps Oefelein and Chen to accurately analyze and visualize large volumes of data. “It’s a lot easier to examine visual images than it is to wade through numbers or statistics,” says Chen. “By looking at isocontour plots or volume renderings, we can see what’s going on at a broad perspective and then zoom in and gather statistics at a finer level.”

Seeing the data visually also helps with diagnostics. “If there’s a problem with the way the code or numerical parameters were set up, it’s much faster to spot these anomalies visually than by printing out rows and rows of numbers,” says Chen.

Finally, Tecplot 360 helps Oefelein and Chen present their results in a way that’s easy for others to grasp. “Visualization software guides both our research and our presentation of results,” says Oefelein. “When we’re done and we’re ready to publish a paper, it helps us to tell our story and summarize what we saw in a nice, concise way.”

“When we’re done and we’re ready to publish a paper, it [Tecplot 360] helps us to tell our story and summarize what we saw in a nice, concise way.”

Diversifying Our Energy Resources

Optimizing the internal combustion engine to work with alternative fuels is an important challenge – one that could significantly affect the future health and stability of the planet. By using Tecplot 360 to help them sort through their computationally-intensive data, Oefelein and Chen are getting closer to the goal of developing the underlying fundamental understanding that is required to ultimately develop predictive models that will help reduce our reliance on fossil fuels.

“A lot of this research can have a huge impact if we just keep at it,” says Oefelein. “It’s definitely not a solved problem, but it’s an important problem. It’s worth putting our effort into.”