November 2010

When Adam Hapij, senior associate at the structural engineering firm Weidlinger Associates, recently visited his son’s kindergarten class, he tried to explain what he does in a way a 5-year-old could comprehend. In the end, he simply said, “I protect people.”

Indeed, at its very core, Hapij’s job is to protect people. Since Weidlinger opened for business more than half a century ago, the company has designed all kinds of structural systems in the U.S. and abroad, including museums, courthouses, and embassies. The firm uses advanced analysis to solve problems of national importance that concern the safety of tall buildings, infrastructure, and military installations.

Weidlinger was the chief engineering firm analyzing the collapse of the World Trade Center towers. The firm also designed a more robust replacement of Oklahoma City’s Alfred P. Murrah Federal Building after it succumbed to progressive collapse, as well as other new structures, including the U.S. Embassy in Berlin, to shield occupants from terrorist acts. Weidlinger designed elements of the new signature span of the San Francisco-Oakland Bay Bridge to withstand an 8.0-magnitude earthquake, and improved the aerodynamic stability of the Bronx-Whitestone Bridge. The firm also studies the effect of underwater explosions and mine detonations on the structural integrity of warships and submarines for the U.S. Department of Defense.

To develop the very detailed analyses needed to make structures safer, Hapij and fellow engineers at Weidlinger use Tecplot 360, a numerical simulation and computational fluid dynamics (CFD) visualization tool, to create state-of-the-art visual simulations. Tecplot 360 enabled them to quickly make sense of vast amounts of complex information.

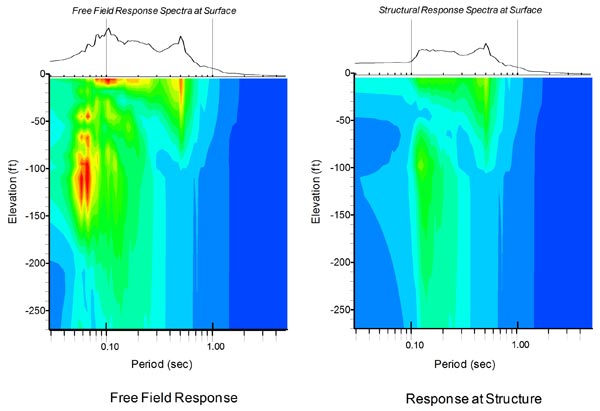

Determining how explosions and other extreme scenarios influence the structural integrity of a building, bridge or submarine requires complex calculations that can only be made with advanced computer modeling. To analyze how structures deform under extreme loads, Weidlinger engineers develop sophisticated computer models and use Tecplot 360 to analyze the results in a clear and concise manner.

“Just think of it in terms of post processing,” says Hapij. “You’ve conducted your analysis, you have a vast amount of data and now you have to somehow harness it to understand what has actually been computed. Tecplot 360 offers many different ways to look at the data. And because you can see a lot of data at the same time, you can develop the biggest possible picture.”

Visualizing the Effects of Blasts on Structures

Weidlinger uses Tecplot 360 for a wide range of projects from retrofitting existing structures to building new structures and vessels that can resist explosions and other extreme events.

To do so, they calculate the scenarios or conditions that would cause the structural element that’s being targeted – a column, for example – to fail. Then they determine how much of the remaining structure would also fail as a result of the column being destroyed. With this knowledge, Weidlinger engineers can systematically remove the key gravity load carrying elements from the perimeter of the structure and confirm the results. They can also design the remaining structure to redistribute the loads without causing a large-scale collapse.

Hapij also works with the U.S. Department of Defense to study the way submerged structures respond to explosions. By analyzing the effect of varying pressures on different parts of the cylinder, he and his team develop a model that numerically predicts when a cylinder will implode underwater as well as the mode of the collapse.

Whether the explosion is above ground or in the ocean, engineers view the event in terms of a propagating wave front. Radiating from a point of local failure, the wave can cause an adjacent structure to lose stability, unless the structure successfully redistributes its loads.

Tecplot 360 is ideal for exploring a number of “what-if” scenarios in rapid succession, according to Hapij. “Modeling a significant amount of fluid at a high resolution and being able to see the propagation of the pressure wave in 3D is not a trivial task,” he says. “Using Tecplot 360, we’ve been able to see both the structural deformations and the colored contours representing different intensities of water pressure.”

The Tecplot 360 Advantage

Weidlinger’s engineers throughout the U.S. and the United Kingdom have integrated Tecplot 360 with the firm’s own simulation software to easily generate detailed 2D and 3D visualizations of structural behavior.

“We’ve interfaced with the Tecplot 360 software in a way that we can write out PLT files directly. This allows us to read the data promptly in whatever style we wish,” says Hapij. “We also rely on macros quite a bit to generate animations. We use the animations for a number of purposes, but first and foremost, we use them for presenting information to clients.”

For example, the firm has been able to create 3D progressive collapse visualizations that combine the effects of several types of loads, such as blast, seismic shaking, and crash impact, to determine where a structure may be vulnerable. Taking slices of the data, engineers can see where there are errors in the data, and go back and rework the analysis. Once the data is completely accurate, they can easily interpret this information to improve their designs.

“Being able to take cuts through the data in Tecplot 360 is fantastic,” says Hapij. “It allows us to get a very quick understanding of what’s happening in the entire data set.”

One benefit of Tecplot 360 is its ability to handle large amounts of data, which enables Weidlinger’s engineers to get a clear picture of how an explosion affects a structure and present this information to clients visually.

“Before, in some cases, we had to actually slice through the data outside of the software and bring it into the application in pieces,” Hapij says. “Now we can do it as a straight shot. The more you see in a single frame, the better overall picture you get.”

The ability to animate large amounts of data also makes it possible for engineers to interpret data quickly. “In days past, if you had a very large representation of a structure, just being able to refresh the data on the screen would be inconceivable,” Hapij says. “Files that couldn’t even load before because they were too big are now easy to view. That saves us a lot of time.”

Finally, Tecplot’s powerful analysis tools and sophisticated visual output make it possible for Weidlinger to obtain highly accurate pictures of its data. “When you have files that involve 100 megabytes of input and gigabytes of output, reviewing them can be a daunting task,” Hapij says. “The visual screening methods offered by Tecplot 360 give us the quality control we need.”

These benefits, in turn, make it possible for Hapij and his colleagues to offer better and faster recommendations to their clients, resulting in more secure structures at lower costs. “The sooner we can obtain some level of confidence, the sooner we can begin development,” says Hapij. “Without this confidence, decisions made in early phases of design may need to be modified later, which increases the cost.”

Designing a Safer Future

Hapij and other engineers at Weidlinger are striving to make the world safer by designing more secure structures, and Tecplot 360 is helping them to achieve their goal.

“Using Tecplot 360 helps us to make sense of what happened and why, as in the case of a structure that has already collapsed,” says Hapij. “It also helps us predict what may happen and why, enabling us to design more secure structures. This understanding moves us that much closer to our goal of protecting structures and the people who use them.”