University of California Researchers use Tecplot 360 CFD visualization software to help identify vortex abnormalities

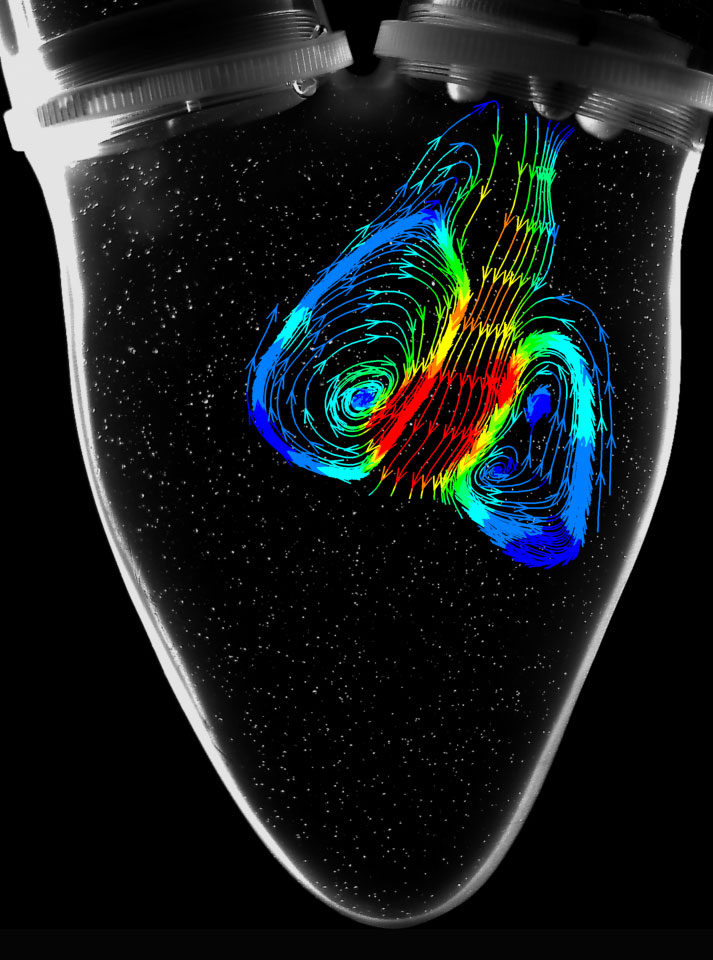

Streamlines of the transmitral jet colored by velocity magnitude. Image credit: Kheradvar A. and Falahatpisheh A., The Effects of Dynamic Saddle Annulus and Leaflet Length on Transmitral Flow Pattern and Leaflet Stress of a Bi-leaflet Bioprosthetic Mitral Valve, J of Heart Valve Disease.

In 1960, Dr. Albert Starr successfully implanted the world’s first prosthetic heart valve, a mechanical device that he co-invented with M. Lowell Edwards, a prominent engineer. More than 50 years later, millions of patients’ lives have been saved or improved by technological advancements based on the work of pioneers like Dr. Starr, Edwards, and others. Today, more than 250,000 patients worldwide receive prosthetic heart valves each year, and that number is growing. Yet, there remains more work to be done. Patients who underwent heart valve replacement experience a better quality of life. However, complications can occur due to device failure, damage to the valve caused by infection, poor valve design, material deterioration, or host tissue overgrowth.

Ahmad Falahatpisheh, a Ph.D. candidate in the lab of Dr. Kheradvar (KLAB) at the University of California, Irvine, is at the forefront of pioneering research to improve bioprosthetic heart valves (BHV) and patients’ quality of life. With the help of Tecplot 360 CFD visualization software to view and analyze his Digital Particle Image Velocimetry (DPIV) data, Falahatpisheh is helping develop the first bileaflet bioprosthetic mitral valve with a dynamic saddle annulus designed to mimic the natural mitral valve. Flow features, such as vortices, developed through this valve are very similar to their counterparts in the natural valve. In addition, the dynamic rather than rigid annulus greatly reduces the stress at the tip of the leaflets.

Excessive stress at the tip can cause leaflet damage. The stress reduction is mainly due to the dynamic annulus, made of Nitinol, which adapts itself to the motion of the cardiac base in the heart cycle. (1) The result of this exciting research will appear in the Journal of Heart Valve Disease.

Making Safer, More Efficient Prosthetic Heart Valves

There are two types of artificial valves available today: mechanical heart valves (MHV), such as the Starr-Edwards device, and biological valves made from tissue material, also known as bioprosthetic heart valves. There are advantages and disadvantages to both types. BHVs have excellent hemodynamics leading to a reduction in the risk of blood clots. However, they wear out and usually require replacement within 10 to 15 years in older patients and much sooner in younger patients. Mechanical valves have superior durability and can last a lifetime, but they can cause blood clots with life-threatening consequences, therefore requiring patients to take blood thinners for the rest of their lives.(2)

Most research today is focused on BHV because they cause fewer side effects and can closely mimic natural flows, when compared to MHV. If researchers are able to increase the lifetime of BHV, then in most cases it would be a better replacement option for patients.

Artificial Heart Flow Simulator while laser is running. Image credit: Ahmad Falahatpisheh, University of California, Irvine

Heart valves tend to calcify around the tip, potentially as a result of excessive stress. The calcification can lead to fatigue, tearing, and ultimately valve failure if the valve is not replaced. By reducing the stress and subsequent calcification, researchers can improve the longevity of the valve.In particular, Falahatpisheh has been evaluating BHV assembled in an artificial heart flow simulator to examine the transvalvular flow with the help of high speed DPIV. Using Tecplot 360, he is able to import DPIV data related to the flow through a valve and identify potential anomalies. Eliminating anomalies clears the way for the design and development of BHV, more specifically for KLAB’s dynamic and bileaflet mitral BHV.

Leveraging High-Speed PIV to Develop Prosthetic Heart Valves

As with any medical device that is implanted in a patient, a crucial step in its development is to ensure that the device successfully passes a stringent set of standards.

To improve these standards scientists should pay attention to the generated flow features as well as the structure of the prosthetic heart valves. “The flow features through a prosthetic heart valve are very important. It’s not only the solid design. You know you can test the valve with a fatigue test and determine that it’ll last a long time, but if you don’t get the correct flow features, it’ll affect the efficiency of the heart,” said Falahatpisheh. “The artificial heart valves shouldn’t disturb the flow, shouldn’t create stagnation regions, etc.”

Falahatpisheh employs DPIV and Computational Fluid Dynamics (CFD) to assess the flow passing through the valve. Using these techniques, he can determine how closely the artificial valves can mimic the natural valve and ensure they are compliant with the standard guidelines.

“The use of high-speed DPIV (1000 fps) at KLAB is unique and to our knowledge, no one else is doing this for the heart valves at this temporal/spatial resolution,” notes Falahatpisheh. “Recall that the resting heart rate of a person is around 70 beats per minute, therefore one cycle takes place in about 860 milliseconds.”

Fluorescent microparticles illuminated by laser sheet at KLAB. Image credit: Paul R. Kennedy

DPIV research on heart valves assures physicians and the Food and Drug Administration (FDA) that the heart valves to be implanted in a patient will operate safely and correctly. To conduct his DPIV studies, Falahatpisheh illuminates fluorescent micro particles on the plane he is interested in gathering data on. From there, he takes 1,000 images per second in order to visualize the flow field.“The beauty of this system is that it’s a high-speed DPIV with 1,000 velocity frames per second,” said Falahatpisheh. “In the past, people could only take images at about 15 frames per second. Our current time resolution is very tiny, one millisecond, which enables us to obtain results that are extremely accurate.”

The Role of CFD Methods and Visualization in the Development of Prosthetic Heart Valves

Many scientists use CFD to study artificial heart valves, as it provides insights into the flow that can benefit the design of the heart valve. The challenge of implementing the proper boundary conditions may lead to deviation from the physical and realistic solution. However, by using DPIV and the artificial heart flow simulator at KLAB, any pulsatile flow similar to the blood flow inside the heart can be experimentally reproduced, eliminating the difficulty of implementing boundary conditions using CFD.

Falahatpisheh imports DPIV data to Tecplot 360 to obtain and visualize flow features through time, which are essential for identifying abnormalities in the flow. He looks at the vortex patterns and identifies valve dysfunctions to help differentiate between a normally functioning heart valve and an abnormal valve. The analysis at this stage is critical: it is essential to have a proper vortex pattern within the flow through the valve. Otherwise, the flow pattern is not optimized to properly transfer the momentum and energy from the heart chamber to the aorta.

From Tecplot 360 results, Falahatpisheh determines how and where to alter the design to ensure a proper flow pattern. If this portion is inaccurate, all the work and research that takes place after the tests will also be inaccurate.

Technology Enabling Development of Longer-lasting Artificial Valves

Technological advances will facilitate the medical industry’s ability to make a greater impact on patients’ quality of life.

Falahatpisheh’s research and use of Tecplot 360 to detect vortex abnormalities will further revolutionize these advancements, particularly by designing a dynamic and bileaflet mitral BHV that will hopefully last the patient’s lifetime. The end goal of his research is to aid in the development and production of a safer and better BHV that helps physicians save more lives and improve their patients’ quality of life.

Ahmad Falahatpisheh is a Ph.D. candidate in the Mechanical and Aerospace Engineering department at the University of California, Irvine. He studies cardiac mechanics, cardiac devices, and cardiac imaging. His current research project is focused on the assessment of mechanical behavior and optimization of a bileaflet bioprosthetic mitral valve by using Finite Element Analysis and Digital Particle Image Velocimetry.

1 Kheradvar A. and Falahatpisheh A., The Effects of Dynamic Saddle Annulus and Leaflet Length on Transmitral Flow Pattern and Leaflet Stress of a Bi-leaflet Bioprosthetic Mitral Valve, J of Heart Valve Disease (Accepted)

2 The Society of Thoracic Surgeons: https://www.sts.org/patient-information/valve-repair/replacement-surgery/mitral-valve-replacement#4